SHIP ТО SHIP TRANSFER GUIDE (PETROLEUM)

(Third Edition 1997)

For Use with Crude

Oil and Petroleum Products

Chapter 9

Equipment

9.1 FENDERS

9.1.1 Fenders

used in STS transfer operations offshore are divided into two categories:

• primary fenders which are positioned along the parallel body of the ship to afford the maximum possible protection while alongside; or

• secondary fenders which may be used to protect bow and stem plating from inadvertent contact during mooring and unmooring.

Primary fenders may be foam filled or of the high

pressure pneumatic type (0.5 to 0.8 Kg/cm2).

Secondary fenders may be either air or foam filled. It can, however, be advantageous for secondary fenders

to be light in weight as they must often be hauled well above the waterline and

located in positions with limited access to lifting gear or support points. It may help if fenders can be moved quickly to counter

possible inadvertent contact.

9.1.2 In most

cases it is probable that tendering operations will be carried out with the

assistance of an STS agency. Such companies usually have service craft available

and these vessels will normally assist in positioning fenders on the relevant

ship.

Fenders may be secured in place on either ship,

however, it is preferable for safety reasons that fenders be secured to the manoeuvring ship. Landing on an unprotected hull section is less likely

if the fenders are rigged on the manoeuvring ship.

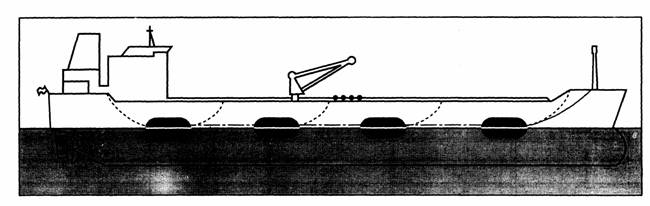

When fenders are fitted to the manoeuvring

ship, primary fenders should be positioned one at each end of the parallel

body, with similar additional units fitted in between. The fender string may be made up to a pre-arranged

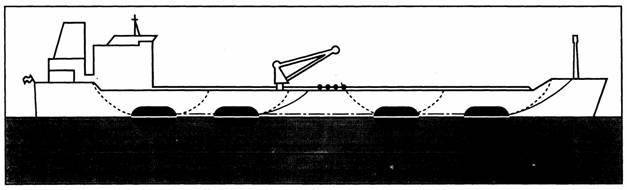

length. Alternatively in some operations, where four fenders

are used it has been found beneficial to position them in two groups of two. In this way, and with each group positioned well

forward or well aft on the parallel body, better protection can be provided. Secondary fenders may be positioned fore and aft of

the parallel body.

The length of the fender string should be such that

the fenders will be able to distribute the maximum anticipated impact load

within the parallel body of both ships.

Table 9.1 is

included to provide a quick reference guide to fender selection and is only

intended to be used to provide an indication of suitability under the

conditions specified. It should be understood that different approach

velocities would give very different energy absorption requirements.

The table should be entered assuming that both vessels

are of the same tonnage (C tonnes) which is

determined from the following formula:

|

C = |

2 x

Displacement Ship A x Displacement Ship B |

|

Displacement Ship A +

Displacement Ship B |

TABLE 9.1 QUICK

REFERENCE GUIDE FOR FENDER SELECTION

|

C Displacement |

Relative Velocity |

Berthing Energy |

Suggested Fender Quantity |

Typical Pneumatic Fender |

|

Tons |

M/Sec |

Ton Mt |

- |

Metres |

|

1,000 |

0.30 |

002.4 |

3 or more |

1.0x2.0 |

|

3,000 |

0.30 |

007.0 |

« |

1.5x3.0 |

|

6,000 |

0.30 |

014.0 |

« |

2.5 x 5.5 |

|

10,000 |

0.25 |

017.0 |

« |

2.5 x 5.5 |

|

30,000 |

0.25 |

040.0 |

4 or more |

3.3 x 6.5 |

|

50,000 |

0.20 |

048.0 |

« |

3.3 x 6.5 |

|

100,000 |

0.15 |

054.0 |

« |

3.3 x 6.5 |

|

150,000 |

0.15 |

071.0 |

5 or more |

3.3 x 6.5 |

|

200,000 |

0.15 |

093.0 |

« |

3.3 x 6.5 |

|

330,000 |

0.15 |

155.0 |

4 or more |

4.5 x 9.0 |

|

500,000 |

0.15 |

231.0 |

« |

4.5 x 9.0 |

Table 9.1 above

gives approximate numbers and sizes for typical pneumatic fenders. Foam filled fenders may differ slightly in size and it

is strongly recommended that individual fender manufacturer/STS agencies are

consulted prior to suggesting number and sizes offenders for a particular

operation.

Further information referring to fender selection can

be found in Appendix 3.

9.1.3 Fender Requirements

Some shipowners and STS

agencies will be able to call upon experience when assessing fender

requirements for a particular STS transfer operation. It is advisable, however, to determine the forces

which will be generated between berthing ships to provide information relevant

to the selection process.

References should be made to individual fender

manufacturer’s specifications and this should be addressed in terms of sea and

swell conditions among other factors.

The fenders used should be suitable in terms of energy absorptions and stand-off distance. The compressed diameter of the fenders must always be sufficient to ensure that there can be no contact between ships' structures through rolling during the period alongside. It is recommended that the fender diameter is less than half the freeboard of the vessel to prevent inadvertent boarding of the vessel by a fender during inclement weather. It should be noted that as it is not always possible to accurately judge approach speed when berthing, it may be prudent to err on the conservative side when selecting fenders. Manufacturers' recommendations for a calm weather situation and a maximum approach speed of e.g. 0.15 m/sec may be inadequate should weather be a factor and approach speed be significantly higher than planned.

FIGURE 9.1:

FENDERS RIGGED IN A CONTINUOUS STRING

FIGURE 9.2:

FENDERS RIGGED IN PAIRS

9.2 HOSES

9.2.1 Hose Standards

The hoses used for crude oils or petroleum products

should be specially designed and constructed for the product being handled.

9.2.2 Hoses

Size and Length

The diameter of a chosen cargo transfer hose is

governed mainly by the required transfer rate and some detail on this subject

is given in Section 9.2.6. Hoses in

excess of 12- inches in diameter will be

progressively more difficult to handle and particular care will be needed to

avoid damage from kinking.

Hose lengths should be adequate to allow for

differences in cargo manifold height, fore and aft alignment and other

differential movements throughout cargo transfer. Generally, total hose length

(consisting of 3 sections of hose) is

between 75 and 90 feet.

For guidance, a rule of thumb for calculating the minimum bending radius (MBR) of a rubber hose is given in this formula:

MBR = Nominal Bore of Hose in inches x 6

(For example a hose of 12 inches nominal bore will give a minimum bending radius of approximately 72 inches.

9.2.3 Hose Connection

STS transfer operations require hose connections to be

well made. Flanges or quick-release couplings if used should be

in good condition and properly secured to ensure leak-tight connections. The gaskets used at the ship's manifolds and between

each hose should be made from a material suitable for the cargo to be

transferred.

Both ships will be expected to provide the necessary

personnel to connect the hoses.

To simplify hose connection, it is recommended that

ships be fitted with cargo manifolds designed in accordance with OCIMF Recommendations

for Oil Tanker Manifolds and Associated Equipment, with regard to flange

sizes, manifold strength, hose support arrangements, lifting gear, etc.

Adequate provision should be made to support hoses to

prevent excessive strain on manifold fittings.

9.2.4 Hose Inspection and Testing

Hoses used should be subject to regular inspection for

damage or deterioration. A record of inspection and pressure/vacuum testing

where relevant should be available.

Periodic testing of hoses should be in accordance with

the requirements of the specification to which the hose was manufactured and/or

as detailed in the OCIMF publication, Guidelines for the Handling, Storage,

Inspection and Testing of Hoses in the Field.

9.2.5 Marking

Each length of hose should be marked by the

manufacturers with:

• the manufacturer's name or trademark;

• identification of the standard specification for manufacture;

• maximum allowable working pressure;

• month and year of manufacture;

• manufacturer's serial number;

• indication that the hose is electrically continuous or electrically discontinuous, semi-discontinuous or anti-static; and

• the words «0il Service».

9.2.6 Flow Velocities

The maximum permissible flow velocity through a hose

is limited by the construction of the hose. The hose manufacturer's recommendations and

certification should give details. Operators should however take other factors into

account when deciding flow velocities.

- These should include, but not be limited to, the following:

- the factor of safety being applied;

- any limitations imposed by flow velocities in the ship's fixed

piping system;

- weather conditions causing movement of the hose;

- age and condition of the hose;

- amount of use and method of storing the hose; and

-

other local considerations.

Tables

9.2 (a), (b) and (c) are indicative of low rates for hoses supplied

under the British standard.

TABLE 9.2(a) THROUGHPUT v. INSIDE DIAMETER AT VELOCITY = 12 M/S.

|

Velocity 12 Metres/Second |

|||

|

Nominal Inside Diameter of Hose |

Throughput |

||

|

Inches |

Millimetres |

Cubic Metres Per Hour |

Barrels Per Hour |

|

6 8 10 12 16 20 |

152 203 254 305 406 508 |

788 1,400 2,180 3,150 5,600 8,750 |

4,950 8,810 13,700 19,800 35,200 55,000 |

TABLE 9.2(b) THROUGHPUT v. INSIDE DIAMETER AT VELOCITY = 15 M/S.

|

Velocity 15 Metres/Second |

|||

|

Nominal Inside Diameter of Hose |

Throughput |

||

|

Inches |

Millimetres |

Cubic Metres Per Hour |

Barrels Per Hour |

|

6 8 10 12 16 20 |

152 203 254 305 406 508 |

985 1,750 2.730 3,940 7,000 10,900 |

6,190 11,000 17,200 14,700 44,000 68,000 |

TABLE 9.2(c) THROUGHPUT v. INSIDE DIAMETER AT VELOCITY = 21 M/S.

|

Velocity 21 Metres/Second |

|||

|

Nominal Inside Diameter of Hose |

Throughput |

||

|

Inches |

Millimetres |

Cubic Metres Per Hour |

Barrels Per Hour |

|

6 8 10 12 16 20 |

152 203 254 305 406 508 |

1,370 2,450 3,830 5,520 9,780 15,315 |

8,600 15,400 24,000 34,500 61,500 96,300 |

Flow rates for different hose velocity ranges can be

calculated using the following formula:

0.785 x D2 x V x 3600 = cubic metres per hour

Where D

is internal diameter in metres and V is velocity in metres per second.

9.3 MOORING EQUIPMENT

It is recommended that all fairleads used during STS

transfer operations are of an enclosed type which will remain effective for

controlling mooring line leads as the freeboard difference between the two

ships changes. Such fairleads should be strong enough to take the

anticipated mooring loads and large enough to allow the mooring line (plus any

soft rope tail and shackle) to pass through comfortably.

Effective leads between fairleads and mooring bitts

and mooring winches should be available for the handling of all mooring lines.

Appropriate fairleads should be fitted to each ship in

order to accommodate a mooring pattern similar to that shown in Figure 6.2. Apart from the need for headlines and sternlines some special needs for springlines

must be considered. It has been found that full strength enclosed fairleads

and bitts for springlines need to be positioned no

more than 35 metres

forward and aft of the cargo manifold.

It is recommended that all tankers be fitted with an

array of mooring bitts of sufficient strength on each side of the ship. A set of bitts should be positioned between each

enclosed fairlead and its attendant winch in order to accommodate an acceptable

mooring arrangement such as that illustrated. In addition it is recommended that provision be made

for securing fender lines.

9.4 GANGWAY

In general it is recommended that the transfer of

personnel between ships be kept to an absolute minimum and much can often be

accomplished by transferring paperwork by heaving line. When transferring personnel from one

ship to the other, a lightweight insulated gangway, complete with safety net

should be made available by either ship to provide safe access between ships. The use of open-rung ladders is strongly discouraged. If available transfer of personnel may

be carried out by use of an approved workboat.

9.5 LIGHTING

During STS transfers at night, normal in-port deck

lighting will be adequate. Portable spotlights, which should be flameproof, and

bridge wing spotlights are useful for night mooring

and unmooring operations.

9.6 REPRESENTATIVE LIST OF EQUIPMENT

Table 9.3

outlines the equipment which might be available for an STS transfer operation. The table has been prepared as an example and is not

intended to be fully comprehensive.

It should be noted that various STS agencies or shipping company «in house» lightening operations may supply different equipment, including supplementary mooring equipment, fender spacing lines, quick release hooks, portable radios, etc., and therefore it is not possible or desirable to provide a comprehensive list of equipment as each case should be considered individually.

Equipment should be suitably sized for the planned

operation bearing in mind the size of ships, the location and the exposure to

climatic conditions.

TABLE 9.3 REPRESENTATIVE

LIST OF EQUIPMENT

|

No. |

Item |

Notes |

|

4 |

Fenders (primary) |

high pressure pneumatic or foam |

|

4 |

Pennants for towing primary fenders |

with hard eye at one end, plus shackles for securing

to fender |

|

4 |

Tail lines for primary fenders |

with hard eye at one end, plus shackles for securing

to fender |

|

2 |

Fenders (secondary) |

lightweight, pneumatic or foam filled, fitted with

synthetic rope pennants |

|

6 |

Cargo hoses |

usually 2

strings of 3 hose lengths, each string

between 75-90 feet long |

|

2 |

Hose and spool pieces |

fitted with vacuum breaker |

|

8 |

Hose straps |

for lifting and support |